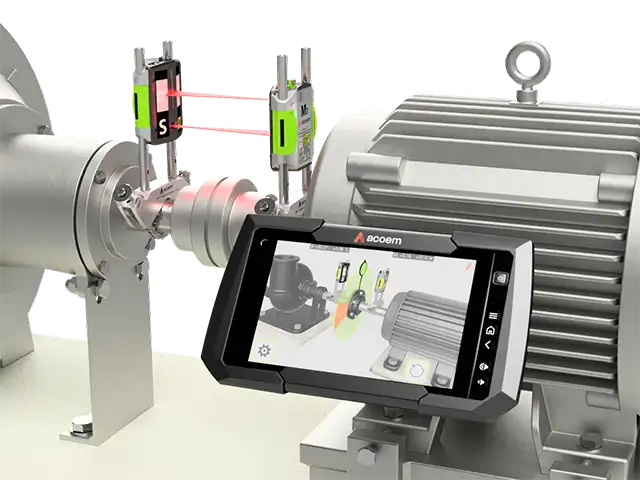

The Smart App-Based Shaft Alignment Solution

The AT-200 is the latest generation of horizontal and vertical laser shaft alignment systems, built upon nearly 40 years of expertise, innovation, and field-proven technology. This solution combines advanced sensor performance, integrated mobile applications, and seamless connectivity to provide unmatched precision and efficiency for modern maintenance teams.

With its intuitive design and powerful features, the AT-200 helps organizations achieve faster, more reliable shaft alignment while reducing downtime, extending equipment life, and optimizing overall operational performance. Whether you are maintaining pumps, fans, gearboxes, compressors, or turbines, the AT-200 is engineered to deliver results that exceed industry expectations.

A Complete Shaft Alignment Toolbox

The AT-200 is more than just a laser shaft alignment tool – it is a comprehensive maintenance toolbox that enables your team to make informed decisions and take corrective actions instantly, right from a smartphone or tablet. By combining cutting-edge sensor technology with smart apps, it empowers users with:

- High-speed, accurate measurement results powered by intelligent wireless sensors

- Simple, user-friendly apps designed for both horizontal and vertical alignment tasks

- Effortless data sharing and report generation through full system connectivity

- Secure cloud integration for trend analysis, storage, and collaborative workflows

The AT-200 package includes everything you need:

- Two high-precision smart wireless sensors with complete accessories

- Dedicated alignment mobile apps for both horizontal and vertical shafts

- Optional Acoem Cloud connectivity for advanced reporting, trending, and remote collaboration

Boosting Your Maintenance Team’s Efficiency

By simplifying the alignment process, the AT-200 allows maintenance professionals to focus on productivity rather than troubleshooting. Its advanced features deliver:

- Accessibility and flexibility: wireless sensors and mobile device compatibility (iOS & Android)

- Time-saving performance: pre-alignment verification in minutes and quick data processing

- Improved reliability: advanced visual guidance that minimizes user errors

- Instant reporting: enabling fast decision-making and immediate corrective actions

Reduce Downtime and Maximize Asset Productivity

Even the smallest shaft misalignment can reduce machinery lifespan by more than 50%. By incorporating AT-200 shaft alignment into your preventive maintenance program, you can proactively eliminate misalignment issues before they lead to costly failures. The result is improved uptime, reduced maintenance costs, and higher productivity across your operations.

- Prevent unexpected equipment failures and costly shutdowns

- Eliminate one of the main causes of premature bearing failure

- Extend the operational life of critical machinery

- Reduce energy consumption by up to 10% through improved alignment

GuideU™ – The Intuitive 3D Graphical Interface

The AT-200 features GuideU™, a patented 3D graphical user interface designed to make shaft alignment easier, more intuitive, and more precise. Using icon-based, color-coded visuals, GuideU™ reduces human error by guiding users through every step of the alignment process. From measuring and correcting misalignments to documenting and generating reports, every task is streamlined with 3D transitions and clear correction values.

This powerful interface ensures that both new and experienced technicians can achieve professional-level results quickly and confidently, improving overall maintenance quality and reliability.

Why Choose the AT-200?

The AT-200 is not just a tool—it is a complete solution designed to elevate your maintenance strategy. By integrating mobility, intelligence, and precision, it provides:

- Faster alignment jobs with minimal downtime

- Unparalleled measurement accuracy for critical rotating machinery

- Full integration with modern digital maintenance workflows

- A future-ready solution adaptable to evolving industrial needs

With the AT-200, your team is empowered with the tools, data, and confidence to maintain alignment excellence and maximize machinery performance.

Users Today : 189

Users Today : 189 Users Yesterday : 236

Users Yesterday : 236 Total Users : 86361

Total Users : 86361